Some fire extinguishers can be used on more than one type of fire. For instance, AFFF extinguishers can be used on both Class ‘A’ fires and Class ‘B’ fires. Your fire equipment supplier will be able to advise you.

Sprinkler System

- Wet type

- Dry type

- Deluge systems

Localized or Total Flooding Fire Suppression System

There are several alternatives to Halon 1301BTM for total flooding or 1211BCF for local systems (which have been banned due to Ozone depletion), that are being deployed, the most common are :

- Gaseous total flooding systems using HFC-227ea (marketed as FM-200 or FE-227), FE- 15,Argotec

- Inert gas blend (marketed as Inergen);

- Water mist systems for gas turbines and similar machinery or

- Pre-action water sprinkler systems.

- Foam-Water Sprinkler

- Water Spray

- Carbon Di-oxide Flooding

These fire extinguishing systems are sometimes used in conjunction with very early warning detection systems that permit manual intervention far in advance of an automatic application of an extinguishing agent.

- Voice Communication (EVAC) Systems

- Emergency Telephone Systems

- Automatic Dry Extinguishing Systems

- Automatic sprinkler systems

- Deluge systems

- Hose reel systems

- Manual fire extinguisher

- Smoke venting systems

- Security Systems

- Access control

- Intruder Alarm

- Closed Circuit Television surveillance

Although these specialized systems all serve different and

individual purposes, they are functionally interconnected to

complement each other in case of an emergency such as fire.

The basic fire alarm system consists of the following components:

- Central fire alarm panel i.e. control unit,

- manually activated signalling boxes (Fire alarm pull boxes),

- Fire detectors and

- Audible alarm (sounders) devices.

- Aids for physically handicapped and visually impaired

A fire detection system, may additionally consist of the following items:

- Tamper switches

- Flow/pressure switches (sprinkler release indication)

- Electronic control unit(s)

- Operation and indication panel(S) -also called terminal(s)

- Remote signalling devices (horns, bells, etc)

- Control outputs to and status input of building services (fans, fire doors, elevators)

- Control outputs to emergency systems (evacuation system)

In case of an alarm, the system may automatically issue various

control signals to in-house equipment, to achieve, for example:

- Automatic return of elevators to the entrance lobby,

- Halting of escalators

- Control of air conditioning system to prevent smoke spread

- Activation of pressurizing fans to supply fresh air to staircases

- Closing of fire doors

- Starting of fire pumps and emergency generators

- Activation of automatic extinguishing equipment

- Control of alarm and voice communication system ( EVAC system)

Most common types of sensors for the detection of smoke and/or fire:

- Heat Detectors

- Fixed or Rate compensated

- Rate of Rise

- Smoke detectors

- Photoelectric Type

- Ionization Type

- Combination Type or “Combo Detector”

- Optical Flame detectors

- Ultraviolet (UV) Sensitive

- Visible Sensitive

- Infrared (IR) Sensitive

- Air Sampling

The designer of modern buildings has never had such freedom from restraint from fire regulations than he has now. The worldwide emergence of a functional approach to the design of buildings is gaining pace with a growing acceptability of alternative solutions. The demand of the designer is solely that he builds a fire safe building. Fire safety practitioners would share the view that traditional fire safety approaches tend to inhibit the design process, and yet, on most occasions, only produce a pseudo-safe building. Using modern methods of smoke containment or smoke ventilation, it is easier to maintain safe egress routes than it has ever been before. As a consequence, the travel distances may be significantly extended, particularly if one uses time-based rather than distance-based criteria.

We as fire Consultants have proficiency in providing :

- Enunciator, Fire Detector, Manual points and Panel layouts

- Control diagram for Main Panels and Remote Panels

- Device and Panel Schedule, Riser Diagram

- Fire Fighting Systems (Hydrants, Sprinklers) ,Inert gas flooding (for Server Room / Record Room etc) Protection of Electrical Panels, LPG Yard / HSD Yard

- Design of Fire Protection System including the furnishing, installation, and connection of the fire alarm equipment to form a complete coordinated system ready for operation. It shall include, but not be limited to, alarm initiating devices, alarm notification appliances, control units, fire safety control devices, annunciators, power supplies, and wiring as shown on the drawings and specified.

- Determine the device types and number of circuits

- Control circuits for integration with Building Management Systems

- Determining the integration requirements with building management systems, automatic dialing and annunciation

- The design and installation of a hydraulically calculated automatic fire sprinkler system complete and ready for operation, for the entire building including the penthouse, mechanical equipment rooms, attic space, elevator machine rooms, elevator pits, linen and trash chutes, and accessible shafts.

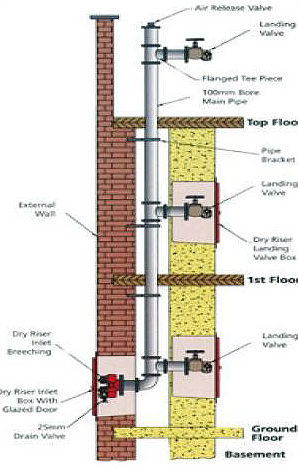

- The design and installation of a standpipe system combined with the sprinkler system

- Installation of a new fire pump (TAC India Approved), sized to meet the system flow and pressure per NFPA 14, NFPA 13 and NFPA 20 the latest editions to provide 430 kPa (65 psi) 690 kPa (100 psi) at the top of standpipe and sized to meet the sprinkler flow and pressure requirements.

- Installation of new sectional valves in the sprinkler/standpipe system feed mains as indicated on the drawings.